Jewellery is not only a symbol of beauty and tradition, but also the result of precision engineering. Behind every sparkling ring, intricate chain, or polished bangle lies a set of specialized jewellery making machines. These machines combine craftsmanship with technology, enabling jewellers to produce consistent, high‑quality designs at scale.

Whether you’re a manufacturer, retailer, or enthusiast, understanding jewellery making machines helps you appreciate how raw materials transform into finished ornaments.

Why Jewellery Making Machines Are Essential

- Precision & Consistency: Machines deliver flawless cuts and repeatable finishes.

- Efficiency: Automated processes reduce production time and material waste.

- Innovation: CNC and laser technologies allow complex, modern designs.

- Scalability: From small workshops to large factories, machines enable growth.

Types of Jewellery Making Machines

Here are the most common machines used in jewellery manufacturing:

- Diamond Faceting Machines

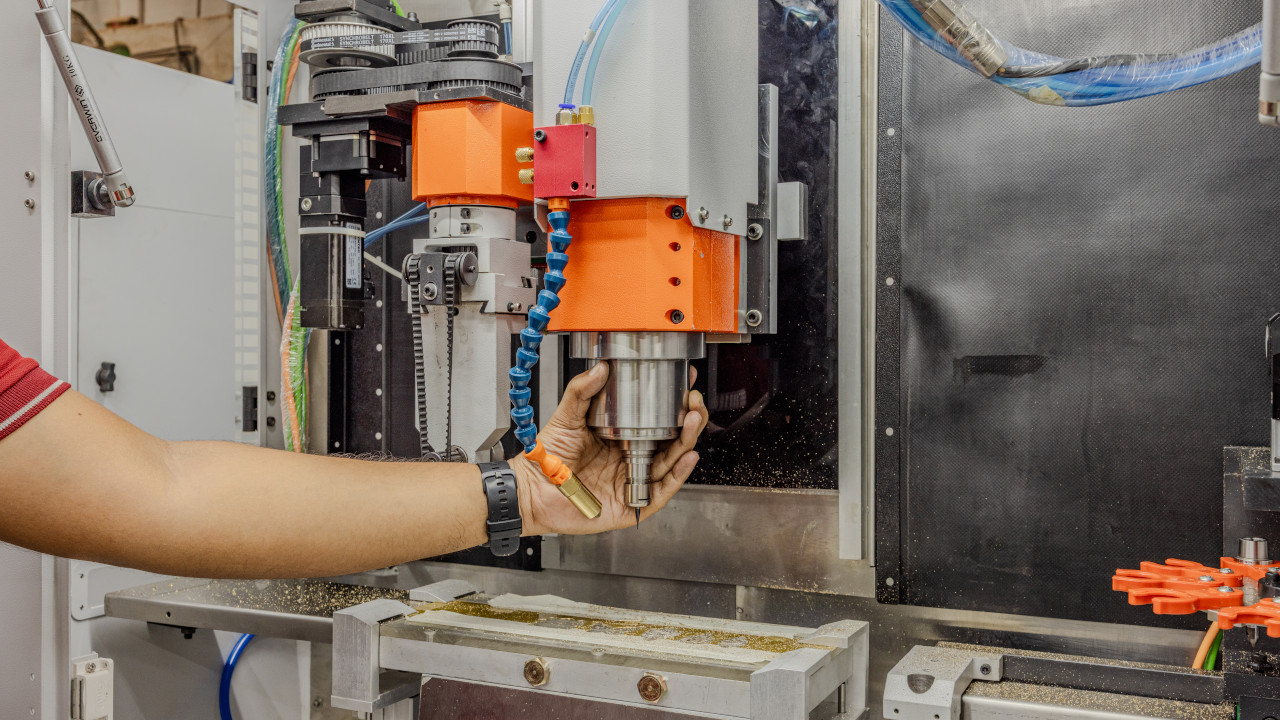

Cut and polish gemstones or diamonds with adjustable angles and CNC precision. Ideal for rings, bangles, and beads. - CNC Jewellery Faceting Machines

Shape facets on metals like gold, silver, and brass. Multi‑axis control ensures repeatability for bangles, chains, and strips. - Rolling Mills

Flatten or shape metal sheets and wires. Adjustable thickness and durable rollers make them essential for producing gold and silver sheets or wires. - Chain Making Machines

Specialized for producing chains in various styles. High‑speed operation and pattern versatility make them perfect for necklaces and bracelets. - Engraving & Laser Machines

Add decorative patterns, branding, or personalization. CNC and laser precision allow ultra‑fine detailing for custom jewellery. - Melting & Vacuum Casting Machines

Melt metals and cast them into molds with controlled temperature and vacuum precision. Commonly used for rings, pendants, and bulk casting. - Lathe Machines

Shape beads, pipes, and bangles with CNC automation. Multi‑head options make them efficient for bead and wire faceting. - Polishing Machines

Provide the final shine and smoothness. High‑speed buffing and dust control systems ensure jewellery pieces are flawless before reaching customers.

Modern Innovations in Jewellery Making Machines

- CNC Automation: Guarantees repeatability and complex geometries.

- Laser Engraving: Enables ultra‑fine personalization.

- 3D Printing Integration: Used for prototyping and mold creation.

- Eco‑friendly Casting: Machines designed to reduce emissions and recycle materials.

Benefits for Jewellers & Manufacturers

- Consistent Quality: Every piece meets international standards.

- Customization: Machines support bespoke designs with minimal manual effort.

- Cost Savings: Reduced scrap and optimized production cycles.

- Global Competitiveness: Advanced machinery helps meet export requirements.

Conclusion

Jewellery making machines are the backbone of modern jewellery manufacturing. From diamond faceting machines to chain making machines, they empower artisans to blend creativity with precision. Investing in the right equipment ensures not just productivity, but also a reputation for excellence in the jewellery industry.

Ready to explore which jewellery making machines are right for your business? Contact our team today to discuss your requirements, request detailed specifications, or book a consultation. Let’s build your next success story together.