R&D Capabilities

Advanced Research & Development Capabilities

At Solanki Mechanic Works, Research & Development (R&D) is at the core of our growth and innovation strategy. Our dedicated R&D team continuously works to develop advanced, user-friendly, and efficient machinery solutions tailored to the evolving needs of the global jewelry manufacturing industry.

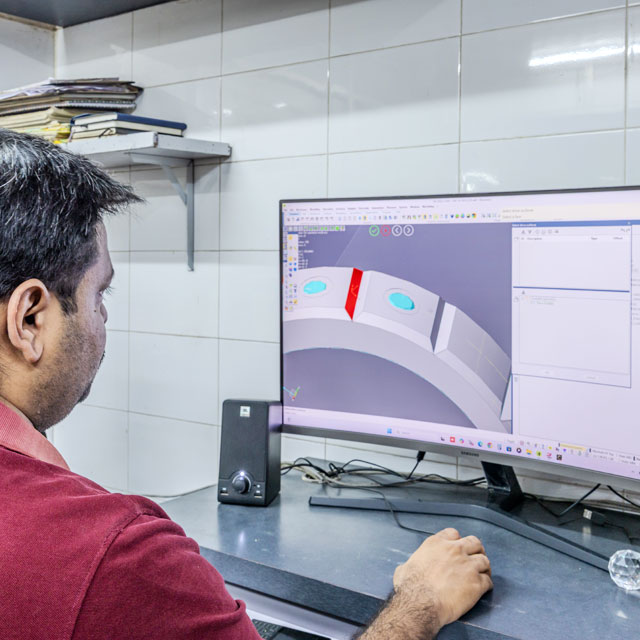

We invest heavily in innovation, prototyping, and continuous improvement, enabling us to transition from conventional machines to highly sophisticated PLC and CNC-based systems. Every new machine begins with a concept, designed and simulated using advanced software tools like Unigraphics NX-2, VISI, and Carveco, allowing us to test and refine ideas long before physical production begins.

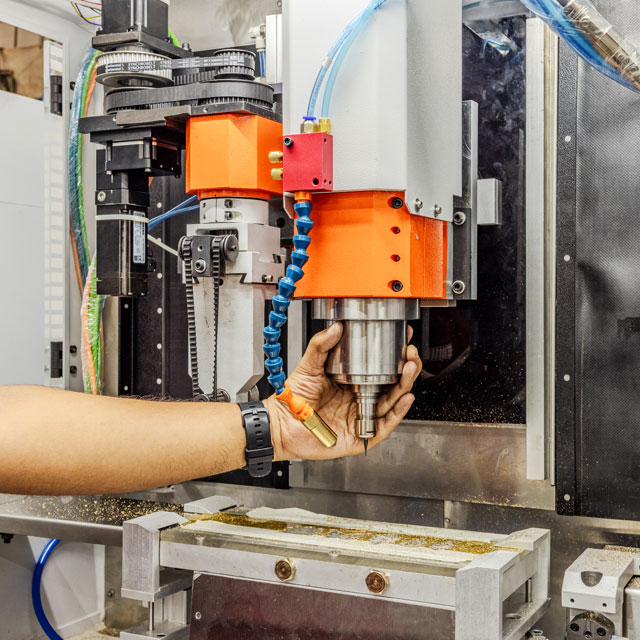

Our in-house prototyping and 5-axis machining capabilities, supported by high-speed, precision equipment, allow us to rapidly bring new designs to life — with accuracy, repeatability, and performance as our benchmarks. This agility helps us stay ahead in an increasingly competitive and technology-driven industry.

Through a culture of experimentation, customer feedback, and technical collaboration, our R&D department ensures that every machine we produce is smarter, faster, and more precise than the last.